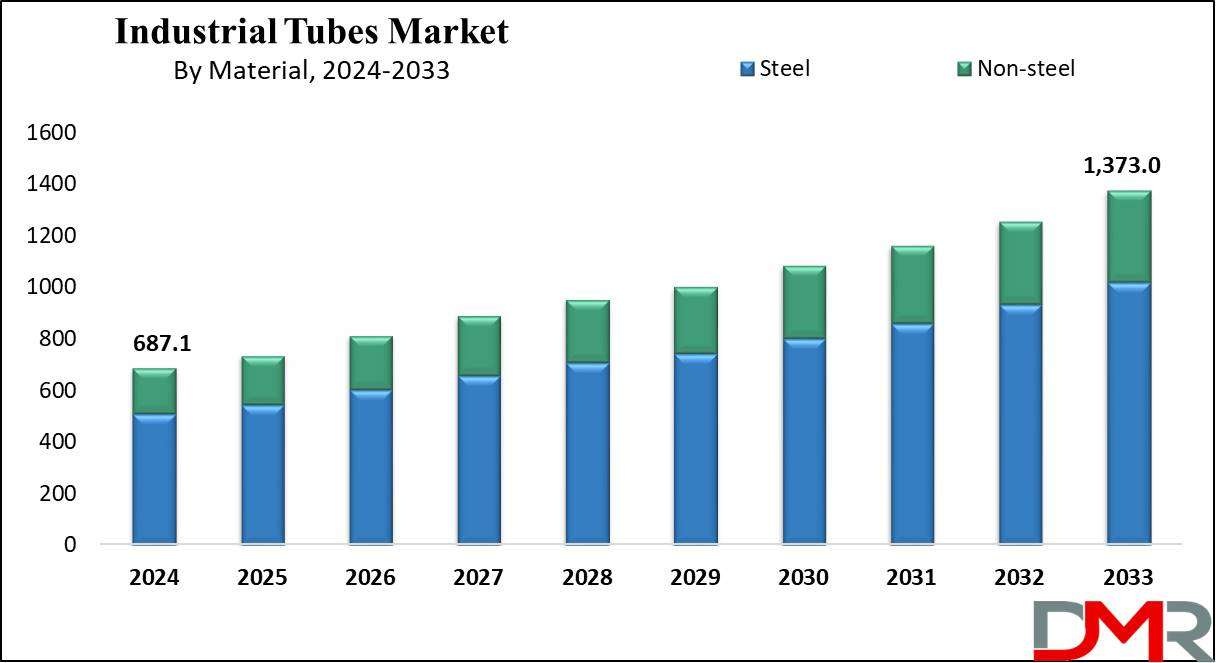

The Global Industrial Tubes Market is witnessing significant growth as industries worldwide increasingly rely on tubing solutions for fluid transport, structural applications, electrical sheathing, and industrial automation. Industrial tubes, which are hollow cylinders designed for efficient material handling, cooling, and energy transfer, are integral to manufacturing, chemical processing, construction, and automotive applications. The market is expected to be valued at USD 687.1 billion in 2024 and is projected to reach USD 1,373.0 billion by 2033, registering a robust compound annual growth rate (CAGR) of 8.0%. This growth is driven by rapid industrialization, urbanization, and technological advancements that enhance the functionality and efficiency of tubing systems across diverse applications.

Market Overview

Industrial tubes serve a critical role in various sectors, facilitating fluid transport, structural support, and electrical insulation. In manufacturing and automation systems, tubes are used for pneumatic and hydraulic operations, material conveyance, and cooling mechanisms. In construction, they provide essential structural support for frameworks, pipelines, and energy distribution networks. The chemical and pharmaceutical industries rely on corrosion-resistant and high-durability tubes to ensure safe handling of chemicals and liquids, while the automotive and aerospace sectors utilize specialized tubing for fluid transfer, cooling systems, and fuel delivery.

The increasing adoption of advanced materials, such as stainless steel, aluminum, and polymer composites, is enhancing the performance and longevity of industrial tubes. These materials offer superior resistance to corrosion, high pressure, and extreme temperatures, enabling broader applications in demanding industrial environments. The market is further supported by rising demand from emerging economies where industrialization and infrastructure development are accelerating rapidly.

Market Dynamics

Drivers

Several factors are fueling the growth of the Industrial Tubes Market. First, the expansion of industrial manufacturing activities across Asia-Pacific, North America, and Europe is creating a steady demand for tubes in process automation, fluid handling, and structural support. Second, the construction sector’s growth, driven by urbanization and infrastructure projects, is increasing the demand for tubes in pipelines, scaffolding, and structural applications. Third, the need for energy-efficient and safe fluid transport systems in chemical, pharmaceutical, and food processing industries is driving adoption of high-performance tubing materials. Additionally, technological advancements in tube manufacturing, including seamless production, precision engineering, and surface coating technologies, are improving product quality and widening their applications.

Restraints

The market faces challenges, including fluctuations in raw material prices, particularly steel, aluminum, and polymers, which can impact production costs. Environmental regulations and safety standards governing the use of materials in chemical and industrial applications may require additional compliance investments. High costs associated with custom-designed or specialized tubes may limit adoption in smaller-scale industrial operations. Moreover, competition from alternative fluid transport and structural solutions, such as flexible hoses and pre-fabricated piping systems, may restrain market growth in certain applications.

Opportunities

The Industrial Tubes Market presents multiple opportunities for growth. The rising adoption of smart manufacturing and Industry 4.0 technologies opens avenues for automation and precision fluid handling, increasing demand for high-quality tubes. Emerging markets in Asia-Pacific and Latin America offer growth potential due to ongoing industrialization, infrastructure development, and rising demand for chemical, automotive, and construction applications. Opportunities also exist in developing specialized tubes for high-temperature, high-pressure, and corrosive environments, as well as tubes designed for renewable energy applications, such as solar thermal systems and hydrogen transport. The expansion of e-commerce and bulk packaging industries further drives demand for durable and versatile tubing solutions.

Segmentation Analysis

By Material: Industrial tubes are manufactured using a variety of materials including stainless steel, carbon steel, aluminum, copper, and polymers. Stainless steel dominates the market for applications requiring corrosion resistance, durability, and high-temperature tolerance. Aluminum and polymer tubes are preferred in lightweight structural applications and fluid handling where corrosion resistance and ease of installation are essential. Carbon steel tubes find usage in heavy industrial and construction applications due to their high strength and cost-effectiveness.

By Application: Industrial tubes are utilized in fluid transport, structural support, electrical sheathing, pneumatic and hydraulic systems, chemical handling, and energy transfer. Fluid transport applications remain the largest segment due to extensive demand in chemical processing, oil and gas, and water distribution systems. Structural applications are growing in construction and manufacturing, while specialized tubes for electrical insulation and thermal energy transfer are witnessing increasing adoption in electronics, automotive, and renewable energy sectors.

By Industry: The industrial tubes market serves automotive, construction, chemical, pharmaceutical, energy, aerospace, food and beverage, and water treatment sectors. The automotive industry employs tubes for fuel lines, hydraulic systems, and cooling mechanisms. The construction industry uses tubes in pipelines, scaffolding, and structural frameworks. Chemical and pharmaceutical sectors utilize corrosion-resistant tubes for safe handling of hazardous liquids and gases. The energy and aerospace industries increasingly require high-performance tubes for fuel transport, thermal energy systems, and hydraulic applications.

By End-Use: Industrial tubes are supplied to OEMs, industrial service providers, and construction companies. OEMs integrate tubes into machinery, vehicles, and equipment, while industrial service providers use tubes for process automation and infrastructure projects. Construction companies rely on tubes for pipelines, structural support, and energy distribution systems.

Regional Analysis

Asia-Pacific is projected to lead the Industrial Tubes Market in 2024, commanding a 41.7% market share due to rapid industrialization, urbanization, and growth in manufacturing and construction sectors. Countries like China and India are witnessing significant infrastructure development, higher usage of chemical products, and expansion in construction chemicals, industrial bulk packaging, and plastic compounding industries, all contributing to increased demand for durable tubing systems.

North America and Europe represent mature markets, with strong demand from automotive, aerospace, and energy sectors. Stringent quality and safety standards, along with technological advancements, are key drivers in these regions. The Middle East and Latin America are emerging markets where industrial growth and energy sector expansion are creating new opportunities for industrial tube applications.

Download a Complimentary PDF Sample Report : https://dimensionmarketresearch.com/report/industrial-tubes-market/request-sample/

Competitive Landscape

The Industrial Tubes Market is highly competitive with global and regional players focusing on product innovation, strategic partnerships, and capacity expansion. Major companies emphasize manufacturing high-performance tubes using advanced materials and precision engineering techniques. Investments in automated production lines, research and development, and quality certifications help maintain product reliability and compliance with international standards. Companies also explore mergers, acquisitions, and collaborations to expand their geographic reach and enhance service offerings. Strategic initiatives include developing lightweight, corrosion-resistant, and high-temperature-tolerant tubes tailored to industry-specific requirements.

Technological Advancements

Technological innovations are enhancing product quality, operational efficiency, and application versatility in the industrial tubes market. Seamless tube manufacturing, cold drawing, extrusion, and surface coating techniques improve strength, durability, and corrosion resistance. Automation in production and precision machining ensures consistent quality for critical applications in automotive, aerospace, and energy sectors. Advancements in polymer composites and hybrid materials allow tubes to meet specialized requirements, including lightweight construction, chemical resistance, and thermal stability. Digital monitoring systems integrated with fluid transport tubes optimize flow rates, reduce leakage, and enhance operational safety in industrial processes.

Sustainability Trends

Sustainability is increasingly influencing the industrial tubes market. Manufacturers are adopting eco-friendly production methods, reducing material waste, and promoting recycling of metals and polymers. Corrosion-resistant and durable tubes reduce maintenance and replacement frequency, contributing to long-term sustainability. Industries are also integrating tubing solutions in energy-efficient systems, including renewable energy infrastructure and thermal energy distribution, aligning with global sustainability goals.

Future Outlook

The Industrial Tubes Market is poised for continued growth through 2033, driven by industrialization, infrastructure development, technological innovation, and rising demand for high-performance materials. Emerging applications in energy, renewable resources, chemical processing, and industrial automation will expand market potential. Companies investing in innovative materials, automated production processes, and industry-specific solutions are expected to maintain a competitive edge. With increasing emphasis on sustainability, safety, and operational efficiency, the market will witness adoption of advanced, versatile, and durable tubing solutions across diverse industrial sectors.

FAQs

What are industrial tubes used for?

Industrial tubes are used for fluid transport, structural applications, electrical sheathing, energy transfer, and material handling in manufacturing and industrial systems.

Which industries are the largest consumers of industrial tubes?

Automotive, construction, chemical, pharmaceutical, energy, aerospace, and manufacturing industries are the primary consumers of industrial tubes.

What materials are commonly used to manufacture industrial tubes?

Stainless steel, carbon steel, aluminum, copper, and polymer composites are widely used, chosen based on strength, corrosion resistance, and application requirements.

What are the key growth drivers of the industrial tubes market?

Industrialization, infrastructure development, technological advancements, energy efficiency needs, and rising demand from automotive and chemical industries drive market growth.

Which region dominates the industrial tubes market?

Asia-Pacific dominates the market due to rapid industrialization, expanding manufacturing sector, and growth in construction and chemical industries.

Summary of Key Insights

The Industrial Tubes Market is projected to reach USD 1,373.0 billion by 2033 at a CAGR of 8.0%. Growth is fueled by industrialization, infrastructure expansion, automotive and chemical industry demand, and technological advancements in materials and manufacturing processes. Asia-Pacific leads the market, while North America and Europe maintain stable demand from mature sectors. Emerging applications in energy, industrial automation, and construction offer growth opportunities. Sustainability, durability, and high-performance tube solutions will shape market trends and drive future adoption across diverse industrial sectors.

Purchase the report for comprehensive details : https://dimensionmarketresearch.com/checkout/industrial-tubes-market/